|

|

|

|

|

|

|

|

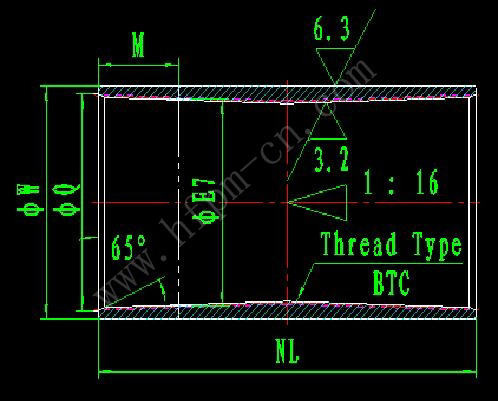

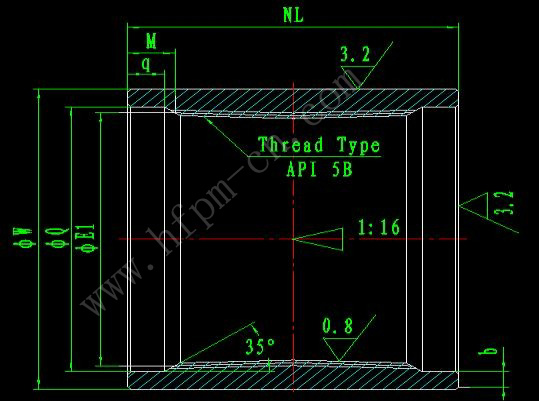

Casing Collar Specifications: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

API Spec 5CT / ISO 11960 |

|

表C.5 化学成分要求(重量百分比) |

| 组别 |

钢级 |

类型 |

碳 |

锰 |

钼 |

铬 |

镍 |

铜 |

磷 |

硫 |

硅 |

| min |

max |

min |

max |

min |

max |

min |

max |

max |

max |

max |

max |

max |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 1 |

H40 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

| |

J55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

| |

K55 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

| |

N80 |

1 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

| |

N80 |

Q |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

| 2 |

M65 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

- |

| |

L80 |

1 |

0.431 |

- |

1.90 |

- |

- |

- |

- |

- |

0.25 |

0.35 |

0.030 |

0.030 |

0.45 |

| |

L80 |

9Cr |

- |

0.15 |

0.30 |

0.60 |

0.90 |

1.10 |

8.00 |

10.0 |

0.50 |

0.25 |

0.020 |

0.010 |

1.00 |

| |

L80 |

13Cr |

0.15 |

0.22 |

0.25 |

1.00 |

- |

- |

12.0 |

14.0 |

0.50 |

0.25 |

0.020 |

0.010 |

1.00 |

| |

C90 |

1 |

- |

0.35 |

- |

1.20 |

0.252 |

0.85 |

- |

1.50 |

0.99 |

- |

0.020 |

0.010 |

- |

| |

C90 |

2 |

- |

0.50 |

- |

1.90 |

- |

NL |

- |

NL |

0.99 |

- |

0.030 |

0.010 |

- |

| |

C95 |

- |

- |

0.453 |

- |

1.90 |

- |

- |

- |

- |

- |

- |

0.030 |

0.030 |

0.45 |

| |

T95 |

1 |

- |

0.35 |

- |

1.20 |

0.254 |

0.85 |

0.40 |

1.50 |

0.99 |

- |

0.020 |

0.010 |

- |

| |

T95 |

2 |

- |

0.50 |

- |

1.90 |

- |

- |

- |

- |

0.99 |

- |

0.030 |

0.010 |

- |

| 3 |

P110 |

5 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

0.0305 |

0.0305 |

- |

| 4 |

Q125 |

1 |

- |

0.35 |

- |

1.35 |

- |

0.85 |

- |

1.50 |

0.99 |

- |

0.020 |

0.010 |

- |

| |

Q125 |

2 |

- |

0.35 |

- |

1.00 |

- |

NL |

- |

NL |

0.99 |

- |

0.020 |

0.020 |

- |

| |

Q125 |

3 |

- |

0.50 |

- |

1.90 |

- |

NL |

- |

NL |

0.99 |

- |

0.030 |

0.010 |

- |

| |

Q125 |

4 |

- |

0.50 |

- |

1.90 |

- |

NL |

- |

NL |

0.99 |

- |

0.030 |

0.020 |

- |

1

若产品采用油淬,则L80钢级的碳含量上限可增加到0.50%。

2

若壁厚小于17.78mm,则C90钢级1类的钼含量无下限规定。

3

若产品采用油淬,则C95钢级的碳含量上限可增加到0.55%。

4

若壁厚小于17.78mm,则T95钢级1类的钼含量下限可减少到0.15%。

5

对于P110钢级的电焊管,磷的含量最大值是0.020%,硫的含量最大值是0.010%。

NL——不限制,但所示元素含量在产品分析时应报告。 |

|

|

|

|

|

|

API Spec 5CT / ISO 11960 |

|

表C.6 拉伸性能和硬度要求 |

|

组别 |

钢级 |

类型 |

加数下的

总伸长率

% |

屈服强度

MPa |

抗拉强度

min |

硬度a

max |

规定壁厚 |

允许硬度

变化b |

| min |

max |

MPa |

HRC |

HBW/- |

mm |

HRC |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 1 |

H40 |

- |

0.5 |

276 |

552 |

414 |

- |

- |

- |

- |

| |

J55 |

- |

0.5 |

379 |

552 |

517 |

- |

- |

- |

- |

| |

K55 |

- |

0.5 |

379 |

552 |

655 |

- |

- |

- |

- |

| |

N80 |

1 |

0.5 |

552 |

758 |

689 |

- |

- |

- |

- |

| |

N80 |

Q |

0.5 |

552 |

758 |

689 |

- |

- |

- |

- |

| 2 |

M65 |

- |

0.5 |

448 |

586 |

586 |

23 |

235 |

- |

- |

| |

L80 |

1 |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

| |

L80 |

9Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

| |

L80 |

13Cr |

0.5 |

552 |

655 |

655 |

23 |

241 |

- |

- |

| |

C90 |

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

≤12.70 |

3.0 |

| |

C90 |

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

12.71--19.04 |

4.0 |

| |

C90 |

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

19.05--25.30 |

5.0 |

| |

C90 |

1、2 |

0.5 |

621 |

724 |

689 |

25.4 |

255 |

≥25.40 |

6.0 |

| |

C95 |

- |

0.5 |

655 |

758 |

724 |

- |

- |

- |

- |

| |

T95 |

1、2 |

0.5 |

655 |

758 |

724 |

25.4 |

255 |

≤12.70 |

3.0 |

| |

T95 |

1、2 |

0.5 |

655 |

758 |

724 |

25.4 |

255 |

12.71--19.04 |

4.0 |

| |

T95 |

1、2 |

0.5 |

655 |

758 |

724 |

25.4 |

255 |

19.05--25.30 |

5.0 |

| |

T95 |

1、2 |

0.5 |

655 |

758 |

724 |

25.4 |

255 |

≥25.40 |

6.0 |

| 3 |

P110 |

- |

0.6 |

758 |

965 |

862 |

- |

- |

- |

- |

| 4 |

Q125 |

1-4 |

0.65 |

862 |

1034 |

931 |

b |

- |

≤12.70 |

3.0 |

| |

Q125 |

1-4 |

0.65 |

862 |

1034 |

931 |

b |

- |

12.71--19.04 |

4.0 |

| |

Q125 |

1-4 |

0.65 |

862 |

1034 |

931 |

b |

|

≥25.40 |

5.0 |

|

a

若有争议时,应采用试验室的洛氏硬度作为仲裁方法。

b

未规定硬度极限,但按7.8和7.9规定限制最大变化量可作为生产控制。 |

|

|

|

|

|

|

|

|

表E.35 API圆螺纹套管接箍尺寸、偏差和重量 |

|

代号1 |

规格a |

外径 W

in |

最小长度

in |

镗孔直径

Q

in |

承载面

宽度b

in |

重量

Ib |

外径

D

in |

短圆

螺纹

NL |

长圆

螺纹

NL |

短圆螺纹 |

长圆螺纹 |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 4-1/2 |

4.5000 |

5.000 |

6-1/4 |

7 |

4-19/32 |

5/32 |

7.98 |

9.16 |

| 5 |

5.000 |

5.563 |

6-1/2 |

7-3/4 |

5-3/32 |

3/16 |

10.27 |

12.68 |

| 5-1/2 |

5.500 |

6.050 |

6-3/4 |

8 |

5-19/32 |

1/8 |

11.54 |

14.15 |

| 6-5/8 |

6.625 |

7.390 |

7-1/4 |

8-3/4 |

6-23/32 |

1/4 |

20.11 |

25.01 |

| 7 |

7.000 |

7.656 |

7-1/4 |

9 |

7-3/32 |

3/16 |

18.49 |

23.87 |

| 7-5/8 |

7.625 |

8.500 |

7-1/2 |

9-1/4 |

7-25/32 |

7/32 |

27.11 |

34.46 |

| 8-5/8 |

8.625 |

9.625 |

7-3/4 |

10 |

8-25/32 |

1/4 |

35.29 |

47.77 |

| 9-5/8 |

9.625 |

10.625 |

7-3/4 |

10-1/2 |

9-25/32 |

1/4 |

39.75 |

56.11 |

| 10-3/4 |

10.750 |

11.750 |

8 |

- |

10-29/32 |

1/4 |

45.81 |

- |

| 11-3/4 |

11.750 |

12.750 |

8 |

- |

11-29/32 |

1/4 |

49.91 |

- |

| 13-3/4 |

13.375 |

14.375 |

8 |

- |

13-17/32 |

7/32 |

56.57 |

- |

| 16 |

16.000 |

17.000 |

9 |

- |

16-7/32 |

7/32 |

76.57 |

- |

| 18-5/8 |

18.625 |

20.000 |

9 |

- |

18-27/32 |

7/32 |

119.07 |

- |

| 20 |

20.000 |

21.000 |

9 |

11-1/2 |

20-7/32 |

7/32 |

95.73 |

126.87 |

|

见图D.1和D.2

a

接箍的规格代号和相应的管子规格代号相同。

b

对于第1、2和3组,外径W的偏差为±1%,但不大于±1/8in。

c

对于第4组,外径W的偏差为+1/8in,但不大于+1/2in -1/16in。

d

对于所有组,镗孔直径Q的偏差为+0.031in -0in。 |

|

|

|

|

|

|

API Spec 5CT / ISO 11960 |

|

表E.36 API偏梯形螺纹套管接箍尺寸、偏差和重量 |

|

代号1 |

规格a |

外径 |

最小

长度NL

in |

镗孔直径

Q

in |

承载面

宽度b

in |

重量

Ib |

外径

D

in |

标准

接箍

W

in |

特殊间

隙接箍

W

in |

标准接箍 |

特殊间隙

接箍 |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 4-1/2 |

4.5000 |

5.000 |

4.875 |

8-7/8 |

4.640 |

1/8 |

10.12 |

7.68 |

| 5 |

5.000 |

5.563 |

5.375 |

9-1/8 |

5.140 |

5/32 |

13.00 |

8.82 |

| 5-1/2 |

5.500 |

6.050 |

5.875 |

9-1/4 |

5.640 |

5/32 |

14.15 |

9.85 |

| 6-5/8 |

6.625 |

7.390 |

7.000 |

9-5/8 |

6.765 |

1/4 |

24.49 |

12.46 |

| 7 |

7.000 |

7.656 |

7.375 |

10 |

7.140 |

7/32 |

23.24 |

13.84 |

| 7-5/8 |

7.625 |

8.500 |

8.125 |

10-3/8 |

7.765 |

5/16 |

34.88 |

20.47 |

| 8-5/8 |

8.625 |

9.625 |

9.125 |

10-5/8 |

8.765 |

3/8 |

45.99 |

23.80 |

| 9-5/8 |

9.625 |

10.625 |

10.125 |

10-5/8 |

9.765 |

3/8 |

51.05 |

26.49 |

| 10-3/4 |

10.750 |

11.750 |

11.250 |

10-5/8 |

10.890 |

3/8 |

56.74 |

29.52 |

| 11-3/4 |

11.750 |

12.750 |

- |

10-5/8 |

11.890 |

3/8 |

61.80 |

- |

| 13-3/4 |

13.375 |

14.375 |

- |

10-5/8 |

13.515 |

3/8 |

70.03 |

- |

| 16 |

16.000 |

17.000 |

- |

10-5/8 |

16.154 |

3/8 |

88.81 |

- |

| 18-5/8 |

18.625 |

20.000 |

- |

10-5/8 |

18.779 |

3/8 |

138.18 |

- |

| 20 |

20.000 |

21.000 |

- |

10-5/8 |

20.154 |

3/8 |

110.45 |

- |

|

见图D.3

a

接箍的规格代号和相应的管子规格代号相同。

b

对于第1、2和3组,外径W的偏差为±1%,但不大于±1/8in。

c

对于第4组,外径W的偏差为+1/8in,但不大于+1/2in -1/16in。

d

对于1、2和3组,外径Wc的偏差为-1/64in +1/32in。 |

|

|

|

|

|

|

|

|

表E.37 API不加厚油管接箍尺寸、偏差和重量 |

|

代号1 |

规格a |

外径

W

in |

最小长度 NL

in |

镗孔直径

Q

in |

承载面宽度 b

in |

特殊倒角的承

载面最大直径

Bf

in |

重量

Ib |

外径

D

in |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 1.050 |

1.050 |

1.313 |

3-3/16 |

1.113 |

1/16 |

1.181 |

0.51 |

| 1.315 |

1.315 |

1.660 |

3-1/4 |

1.378 |

3/32 |

1.488 |

0.84 |

| 1.660 |

1.660 |

2.054 |

3-1/2 |

1.723 |

1/8 |

1.857 |

1.29 |

| 1.900 |

1.900 |

2.200 |

3-3/4 |

1.963 |

1/16 |

2.050 |

1.23 |

| 2-3/8 |

2.375 |

2.875 |

4-1/4 |

2.438 |

3/16 |

2.625 |

2.82 |

| 2-7/8 |

2.875 |

3.500 |

5-1/8 |

2.938 |

3/16 |

3.188 |

5.15 |

| 3-1/2 |

3.500 |

4.250 |

5-5/8 |

3.563 |

3/16 |

3.875 |

8.17 |

| 4 |

4.000 |

4.750 |

5-3/4 |

4.063 |

3/16 |

4.375 |

9.58 |

| 4-1/2 |

4.500 |

5.200 |

6-1/8 |

4.563 |

3/16 |

4.850 |

10.77 |

|

见图D.4

a

接箍的规格代号和相应的管子规格代号相同。

b

外径W的偏差为±1%。 |

|

|

|

|

|